Product name:CP, CPT, CPJ series marine jet pumps

Category:Other pumps

Release time:08-08-2024

Number of views:95

Product Introduction

1、 Overview:

The suction, discharge, and nozzle of the CPJ jet pump are all on the same axis, resulting in high efficiency. The working water pipe is bent in a J-shape, and its flange is perpendicular to the suction and discharge flanges, making installation convenient. No moving parts, long service life. It has self-priming function and can work continuously and stably. Mainly used for ship drainage systems, it can also be used in industries such as environmental protection, chemical engineering, water conservancy, and building materials to extract fresh water from the sea, mix liquids, dredge rivers, and transport powders.

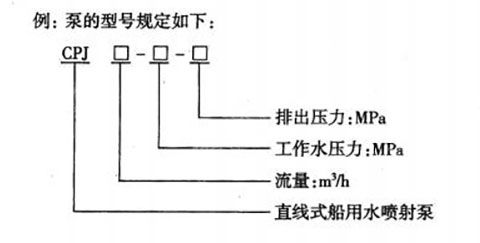

2、 Model Description:

3、 Structure and principle explanation:

Main component description

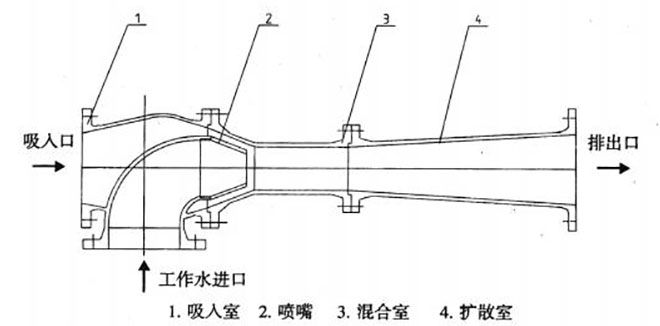

(1) The water jet pump consists of the following main components:

① Inhalation chamber; ② Nozzle; ③ Mixing room; ④ Diffusion chamber.

(2) The nozzle material is generally made of 2CuAI9Mn2 or stainless steel, and the suction chamber, mixing chamber, and diffusion chamber materials are generally made of ZCuZn16Si4 or bronze. After processing, strength tests are conducted according to the specified hydraulic pressure.

(3) The working water inlet, suction inlet, and discharge outlet of the water jet pump are all in the form of ship flanges.

2. Working principle

Water jet pumps rely on liquid impact to transfer energy. Namely, the high-pressure working water flow greatly increases in velocity through the nozzle, forming a high-speed water flow that is ejected, thereby reducing the pressure. Due to the viscous effect between the jet of working water and the air, the high-speed water flow carries away the air at the inlet of the mixing chamber, thus forming a vacuum state. Under the action of pressure difference, the water being sucked is sucked in. The water flow sucked at the inlet of the mixing chamber begins to mix with the high-speed working water flow, collides, and enters the mixing chamber. In this way, the speed of the working water flow decreases, while the speed of the drawn water flow increases, and the speeds of the two water flows gradually converge. Until complete mixing, the pressure inside the mixing chamber gradually increases. The mixed water flow then flows into the diffusion chamber, further converting velocity energy into pressure energy, and is discharged from the outlet of the diffusion chamber.

4、 Usage and maintenance

1. Work process

Firstly, check the sealing condition of each pipeline system. Then, open the valve of the working water pipe slightly to allow the air in the mixing chamber to escape. Then, open all the valves on the suction and working water pipes to ensure the normal operation of the water jet pump. Finally, adjust it to the rated working condition.

2. Comprehensive observation

(1) Check the sealing condition of all connections and ensure there is no leakage during operation.

(2) When performance degradation is found, the sealing condition of each part of the suction section should be checked, and whether there are debris, garbage accumulation or blockage inside the pump, as well as whether the nozzle is worn.

3. Maintenance

(1) After the water jet pump is completed, the valves on the working water pump and suction pipeline should be closed.

(2) After the water jet pump stops working, attention should be paid to the cleanliness of the interior, and sediment such as mud, salt, and other debris should be regularly removed.

(3) Oil seals should be applied to water jet pumps when they are not in operation for a long time. When sealing oil, all parts of the pump must be wiped dry, and all machined surfaces should be coated with industrial Vaseline. Non machined surfaces inside the pump should be coated with red lead paint, and then the inlet and outlet of the water jet pump should be blocked. Remove the blockage at the inlet and outlet of the pump when unpacking, and clean the industrial Vaseline with cotton yarn soaked in kerosene.

- Previous:CYBW series marine air pump

- Next:N-20 self-priming device